How to design & manufacture a PMSM/BLDC Motor Controller?

Designing and manufacturing PMSM/BLDC motor controller requires a comprehensive understanding of various engineering disciplines and the ability to select appropriate materials.

Knowledge Areas:

-

Power Electronics: A deep understanding of power electronics is crucial for designing the power stage of the controller, including selecting suitable power devices (MOSFETs or IGBTs), designing gate drive circuits, and implementing efficient power conversion techniques.

-

Digital Control: Proficiency in digital control theory is necessary to develop the control algorithms for the motor. This includes understanding topics like PID control, field-oriented control (FOC), and state-space modeling.

-

Microcontroller Programming: Familiarity with microcontroller programming languages (e.g., C, C++) is essential for implementing the control algorithms and interfacing with various sensors and peripherals.

-

Electromagnetics: Knowledge of electromagnetic principles is required to understand the interactions between the motor windings and the magnetic field, as well as to design appropriate current sensing and filtering techniques.

-

Thermal Management: Understanding heat transfer mechanisms and thermal design principles is important to ensure the controller's reliability and prevent overheating.

-

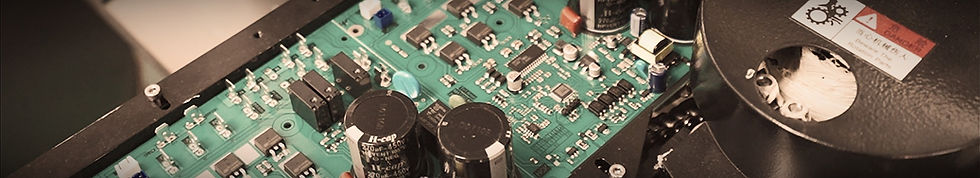

PCB Design: Skill in PCB layout design is necessary to create a reliable and efficient printed circuit board for the controller.

Key Components:

-

Microcontroller: A powerful microcontroller capable of handling the complex control algorithms and real-time processing.

-

Power MOSFETs or IGBTs: High-power semiconductor devices rated for the motor's voltage and current requirements.

-

Diodes: Used for freewheeling and protection.

-

Current Sensors: To measure the phase currents accurately.

-

Voltage Regulators: To provide stable power supplies to the various components.

-

Capacitors: For filtering and energy storage.

-

Inductors: For filtering and current smoothing.

-

Heat Sinks: To dissipate heat generated by the power devices.

-

PCB: The printed circuit board to hold all the components.

-

Connectors: For power input and output, as well as for communication with other systems.

-

Enclosure: To protect the controller from environmental factors.

Additional Considerations:

-

Software Tools: You'll need software tools for circuit simulation, PCB design, and code development (e.g., MATLAB/Simulink, Altium Designer, Keil).

-

Testing Equipment: Oscilloscopes, power supplies, and load banks will be required for testing and debugging the controller.

-

Standards and Certifications: Depending on the application, you may need to comply with relevant safety and EMC standards.

Design Process:

-

Define Specifications: Clearly outline the motor's parameters, desired control features, and operating environment.

-

Select Components: Choose components based on the specifications and trade-offs between performance, cost, and availability.

-

Design the Power Stage: Design the power circuit, including the selection of power devices and the calculation of component values.

-

Develop Control Algorithms: Implement the control algorithms using the chosen microcontroller and programming language.

-

Design the PCB: Create a PCB layout that minimizes noise and maximizes efficiency.

-

Build and Test: Assemble the controller and test its performance under various conditions.

-

Refine and Optimize: Iterate on the design based on test results and feedback.

In summary, designing and manufacturing an 800W PMSM motor controller requires a multidisciplinary skill set and a deep understanding of power electronics, control systems, and hardware design.

To produce a PMSM or BLDC motor controller, you will need the following materials and components:

Main Materials List

-

Microcontroller (MCU)

-

Choose a microcontroller that supports FOC (Field-Oriented Control) algorithms, such as the STM32 series or TI's C2000 series, to achieve efficient motor control.

-

-

Power Drivers

-

Use MOSFETs or IGBTs as power switches, typically requiring six MOSFETs to construct a three-phase inverter circuit.

-

-

Inverter Circuit

-

Design a three-phase inverter circuit, usually in a half-bridge or full-bridge configuration, to convert DC power into AC power.

-

-

Power Supply Module

-

Provide a stable DC power supply, typically 48V DC, to meet the 800W power requirement.

-

-

Brushless DC Motor (BLDC)

-

Select an appropriate 800W brushless DC motor, ensuring that its rated power and speed meet application requirements.

-

-

Sensors

-

Hall effect sensors or encoders for obtaining rotor position and speed feedback to achieve closed-loop control.

-

-

PCB Board

-

Custom design a PCB to accommodate all electronic components while ensuring good heat dissipation and layout.

-

-

Cooling Devices

-

Heat sinks or fans to prevent overheating of power components, ensuring stable system operation.

-

-

Connectors and Cables

-

High-quality connectors and cables to ensure reliable and durable electrical connections.

-

Additional Materials

-

Software Development Tools

-

Software tools and libraries required for developing the FOC algorithm, such as TI's IQmath library or other related software packages.

-

-

Debugging Tools

-

Oscilloscopes, logic analyzers, etc., for debugging and testing controller performance.

-

Summary

Producing a PMSM or Brushless DC motor controller requires various key components, from microcontrollers to power drivers, as well as necessary sensors and PCB design. Choosing the right materials and tools will directly impact the performance and efficiency of the controller.