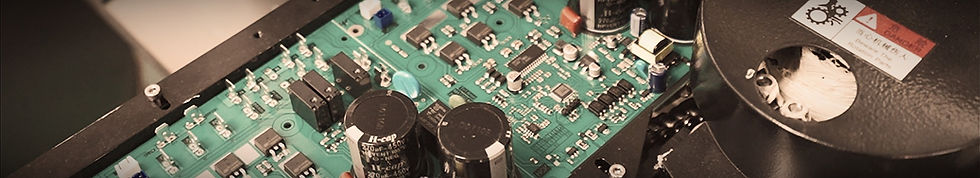

PFC Circuit

Como projetar o circuito PFC no BLDC Motor Driver?

Os circuitos PFC desempenham um papel crucial nos dispositivos eletrônicos modernos, melhorando a eficiência energética e ao mesmo tempo melhorando a estabilidade e a confiabilidade do sistema. A Lumsyn Electronic produz driver de motor BLDC com PFC para refrigerador de ar, ventilador HVLS, bomba de água, máquina de costura, descarte de lixo e mais aplicações.

Visão geral do circuito PFC

Os circuitos PFC (Power Factor Correction) são tecnologias essenciais utilizadas para melhorar a eficiência e a qualidade da energia dos sistemas elétricos. Eles funcionam controlando a forma de onda da corrente de entrada para alinhá-la com a forma de onda da tensão de entrada, aumentando assim o fator de potência e reduzindo os harmônicos. Abaixo está uma visão geral da estrutura principal, princípio de funcionamento e considerações de projeto dos circuitos PFC.

1. Estrutura Básica dos Circuitos PFC

Os circuitos PFC normalmente empregam uma topologia Boost, que permite que a tensão de saída seja superior ao valor de pico da tensão de entrada CA. Os componentes básicos incluem:

-

Retificador: Converte energia CA em CC.

-

Indutor PFC (L): Armazena energia e suaviza a corrente de entrada.

-

Dispositivo de comutação (como MOSFET): Controla a transferência de energia.

-

Diodo Boost (D1): Transfere a energia armazenada para o capacitor do filtro.

-

Capacitor de filtro (C): Suaviza a tensão CC de saída.

4. Growing Demand for Customization and Specialized Applications.

The industry is seeing a surge in demand for customized BLDC motors tailored to specific applications. This requires manufacturers to offer a wider range of motor sizes, configurations, and performance characteristics to meet diverse customer needs. Examples include specialized motors for drones, medical devices, and industrial robots, home & industrial appliances(air coolers, industrial fans, water pumps...)

5. Sustainability and Environmental Concerns.

The emphasis on sustainability is driving the adoption of eco-friendly materials and manufacturing processes in the BLDC motor industry. Manufacturers are increasingly utilizing recycled materials and implementing energy-efficient production methods to minimize their environmental impact.

6. Increased Competition and Consolidation.

The BLDC motor market is becoming increasingly competitive, with both established players and new entrants vying for market share. This is leading to consolidation within the industry through mergers and acquisitions, as companies strive to expand their product portfolios and global reach.

7. Digitalization and Industry 4.0.

The adoption of digital technologies, such as data analytics and artificial intelligence (AI), is improving the efficiency and productivity of BLDC motor manufacturing. This includes predictive maintenance, optimized production processes, and improved quality control.

8. Focus on Reliability and Durability.

In many applications, especially in demanding environments, the reliability and durability of BLDC motors are paramount. Manufacturers are investing in robust designs and rigorous testing procedures to ensure the long-term performance of their products.

In summary, the BLDC motor industry is dynamic and rapidly evolving, driven by technological advancements and the increasing demand for efficient and reliable motors across a wide range of applications. The trends outlined above highlight the key factors shaping the future of this crucial technology.