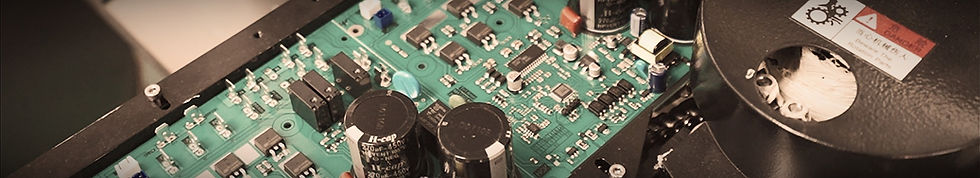

PFC Circuit

Синхронный реактивный двигатель в сравнении с PMSM и асинхронным двигателем

Команда Lumsyn Electronic �занимается исследованиями и разработками высокоэффективных и высоконадежных синхронных реактивных двигателей и использует их в воздухоохладителях, водяных насосах и других продуктах.

Что такое синхронный реактивный двигатель?

Синхронный реактивный двигатель (SynRM) — это специальный тип синхронного двигателя, который использует неравномерное магнитное сопротивление своего ротора для создания крутящего момента. В отличие от традиционных синхронных двигателей, ротор SynRM не имеет ни постоянных магнитов, ни обмоток. Вместо этого он построен из чередующихся ферромагнитных и неферромагнитных материалов. Эта уникальная структура заставляет ротор испытывать магнитные силы при вращении, тем самым создавая крутящий момент.

4. Growing Demand for Customization and Specialized Applications.

The industry is seeing a surge in demand for customized BLDC motors tailored to specific applications. This requires manufacturers to offer a wider range of motor sizes, configurations, and performance characteristics to meet diverse customer needs. Examples include specialized motors for drones, medical devices, and industrial robots, home & industrial appliances(air coolers, industrial fans, water pumps...)

5. Sustainability and Environmental Concerns.

The emphasis on sustainability is driving the adoption of eco-friendly materials and manufacturing processes in the BLDC motor industry. Manufacturers are increasingly utilizing recycled materials and implementing energy-efficient production methods to minimize their environmental impact.

6. Increased Competition and Consolidation.

The BLDC motor market is becoming increasingly competitive, with both established players and new entrants vying for market share. This is leading to consolidation within the industry through mergers and acquisitions, as companies strive to expand their product portfolios and global reach.

7. Digitalization and Industry 4.0.

The adoption of digital technologies, such as data analytics and artificial intelligence (AI), is improving the efficiency and productivity of BLDC motor manufacturing. This includes predictive maintenance, optimized production processes, and improved quality control.

8. Focus on Reliability and Durability.

In many applications, especially in demanding environments, the reliability and durability of BLDC motors are paramount. Manufacturers are investing in robust designs and rigorous testing procedures to ensure the long-term performance of their products.

In summary, the BLDC motor industry is dynamic and rapidly evolving, driven by technological advancements and the increasing demand for efficient and reliable motors across a wide range of applications. The trends outlined above highlight the key factors shaping the future of this crucial technology.